Using Induction Heating Systems To Harden Metals

- Technology

- February 24, 2022

- No Comment

- 26857

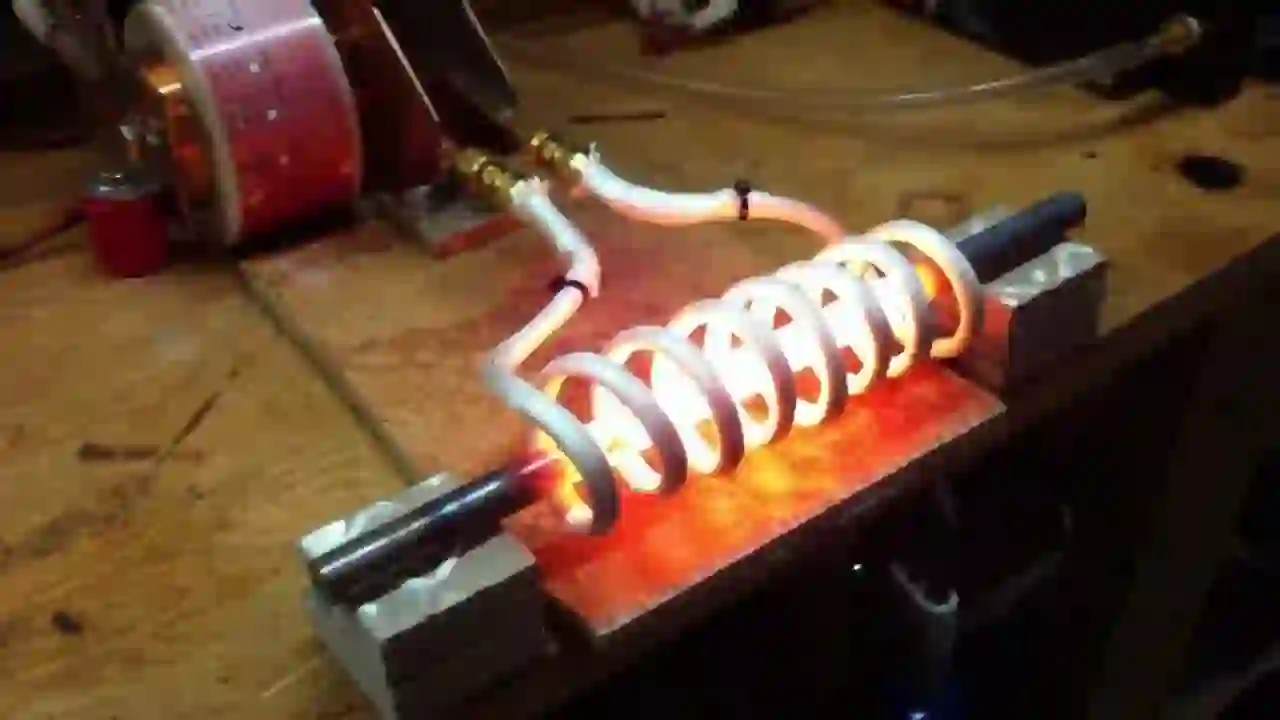

Induction solidifying is a kind of warmth treatment that includes induction heating to warm the metal, extinguished. During the extinguishing cycle, the metal goes through a change that solidifies it, expanding its fragility. The Induction Heating Vessels Reactors frameworks are utilized to solidify the part’s chosen territories or gather, without influencing the properties’ whole part. Induction heating utilizes the rule of electromagnetic induction which is a non-contact heating measure. It produces heat within layer of the workpiece.

When a conductive material is set into a solid, attractive field, electrical flow can stream in the steel making heat. The current that is produced streams chiefly in the surface layer. The layer’s profundity is controlled by surface force thickness, recurrence of exchanging field, the material thickness and porousness, and warmth. The surface layer changes and becomes a lot harder by extinguishing the layer in oil, water or other extinguishing specialists.

The induction solidifying measure is ordinarily utilized for surface solidifying of steel. An attractive exchanging field is utilized to warm the segments to temperatures above or inside the change range, after the extinguishing the centre of the remaining material parts unaltered by the treatment. The actual properties continue as before as those of the first bar, while the hardness is a lot higher. The handheld induction brazing heater is appropriate for carbon and compound prepares with equivalent carbon content. The inside of this framework will contain a copper curl. This curl is perhaps the main pieces to the machine. It is inside this loop that the entirety of the heating happens. In any case, it isn’t merely the curl that will emit the warmth. The article you are setting in the radiator to soften or warm-up will make its warmth. This is how the aluminum melting induction furnace framework works. It causes the item inside to warm up all alone. In any case, it is essential to understand that solitary, electrically conductive materials will work inside these machines.

High recurrence power is essential as an approach to drive the colossal substituting current through a curl. As current goes through the curl, an extreme and quick changing attractive field is produced. The workpiece is set inside the attractive exchanging field, where the flows that are created and the obstruction causes heating of the metal. This is a cycle that is basic with steel composites. A large portion of the mechanical parts that are promptly accessible, for example, cogwheels, shafts and springs are exposed to this treatment to upgrade or improve the quality and wear conduct. The solidifying cycle is an imperative piece of the machine and car industry, just as for different applications that require high protection from wear.

The treatment is viewed as successful, relying upon the surface materials’ adjustment properties as presented by the remaining pressure. Induction solidifying is quite possibly the most well-known cycle utilized in improving the solidness of parts. It transforms the workpiece into an intense centre with adjustable leftover pressure and a hard layer with compressive weight on a superficial level. This cycle has ended up being exceptionally viable regarding broadening the life and obstruction of the part.

An Induction Heating Stress Relieving has numerous utilizations in an assortment of enterprises. When all is said in done, the framework runs an electrical flow through a copper loop that creates an attractive field. The electrically conductive article is put inside the curl where it gets the flow from the copper loop and starts to warm up. This cycle can liquefy metal and play out an assortment of different capacities in different fields. This makes this sort of heating framework a solid match for some enterprises, particularly those where other heating strategies are risky. Visits us https://marketbusinessmag.com/