Using a New Material on an Industrial Valve

- Home Improvement

- November 30, 2022

- No Comment

- 1322

Metal valves are now commonly used industrial valves in a wide range of sectors. Despite the fact that the metal valve has a long history and that its structure and material are constantly being developed, this valve is now unable to meet the demands for high abrasion resistance and high corrosion resistance due to limitations in the metal material’s inherent properties. Modern industrial valves have a limited lifespan in use and significantly impair the stability of system functioning. It is critical to radically innovate the conventional metal valve in terms of its composition, design, and production method. More and more scientists are valuing sophisticated ceramics as the new material of the twenty-first century. The experts believe that incorporating ceramics into industrial van an toàn lò hơi will be a positive breakthrough.

It’s common to think of a ceramic substance as being limited to inorganic crystalline oxides. It is stable and unmoving. In addition, crystal ions produced of ceramics typically have a relatively small radius but a high electrical valence and a large coordination number. Ceramic materials are brittle, hard, strong in compression, yet weak in shearing and tension due to these characteristics. They resist the chemical deterioration that other materials exposed to an acidic or caustic environment experience. Ceramics, on the other hand, can typically endure extremely high temperatures, such as those between 1,000 °C and 1,600 °C (1,800 °F and 3,000 °F). The variety of applications will be constrained by the brittleness of ceramics. However, the brittle property has significantly improved recently due to the development of Martensitic Transformation in Zirconia Toughened Ceramics, composite technology, and nanotechnology. Therefore, this characteristic cannot prevent ceramics from being used in a variety of sectors, including the mechanical, chemical, and petroleum ones. It is also without a doubt a trend for ceramics to gradually replace metal as the material for industrial valves.

When ceramics are used in industrial valves, there will be significant financial advantages. The benefits will be discussed in the information that follows. First, improvements will be made to wear resistance, corrosion resistance, and leak resistance. The industrial valve’s service life will be significantly extended as a result. Second, there will be less opportunity for valve maintenance. The system’s operation will be somewhat more secure and reliable. In the meantime, there will be significant maintenance cost savings. Thirdly, the ceramic valve may increase the industrial pipeline’s leak-proofness and stop the biggest leak. It is highly beneficial to encourage environmental protection at this moment. Last but not least, there is a wide variety of low-cost raw materials available for ceramics. For instance, ordinary raw materials like aluminum and carbon can be used to create ceramics with exceptional qualities. Overall, a future development trend will be the use of ceramics in the manufacture of industrial valves.

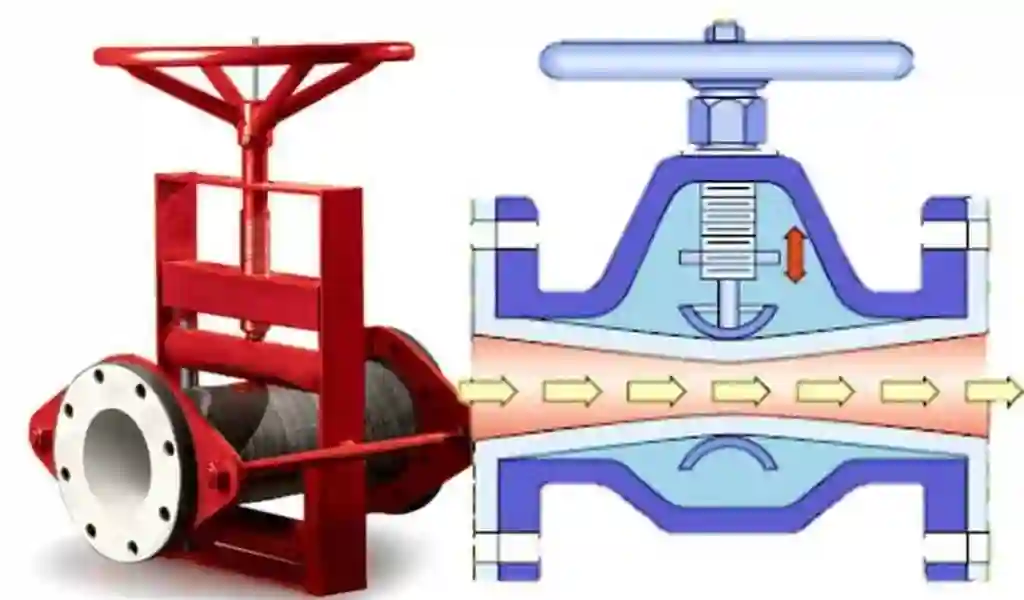

When a minimal flow is required, they are utilized to control fluid flow. Because the component that controls flow either stops or permits it, it is also known as a sluice valve. It has a gate-like quality. These typically have flanged ends that are drilled in accordance with flange dimensions requirements that are compatible with pipelines.

Gate valves, like all other van hơi nóng, have flanged ends to link them to the pipelines. Cast iron, gun metal, stainless steel, or cast carbon steel can all be used to make valves.

Sphere Valves

The name “globe valves” comes from their spherical form. The more recent ones, though, are less spherically formed. When it comes to flow regulation, they offer more accuracy than other varieties. Globe valves are utilized in situations where the flow must be precisely controlled. According to Peco Company, they have a plate with a hole in it, and a disk or plug totally or partially fits into the hole, slowing or stopping flow.

Check valves that swing

When compared to other kinds of popular valves, these are less frequently employed. The swing check is firmly pressed against the valve seat when there is reverse flow, reducing system losses.

When the power is out, swing check valves work well to keep the pump primed. They stop water from the filter from backing up into the pond. They come in numerous sizes and numerous varieties.